About

What we do:

More than 3000 children every year are born with a congenital limb deficiency in the United States alone. These children will change their prosthetics devices once every 6 months on average, making the purchase of a high end, automatic prosthesis not affordable for most families.

The advent of affordable 3D printers spawned numerous customizable and very affordable prosthetic hand models. These devices can be modified to fit the children as they grow, at a relatively low price. However, these prosthetic hands leave a lot to be desired in functionality. Most of these devices can only allow coarse finger control, placing it in stark contrast to commercial automatic hands.

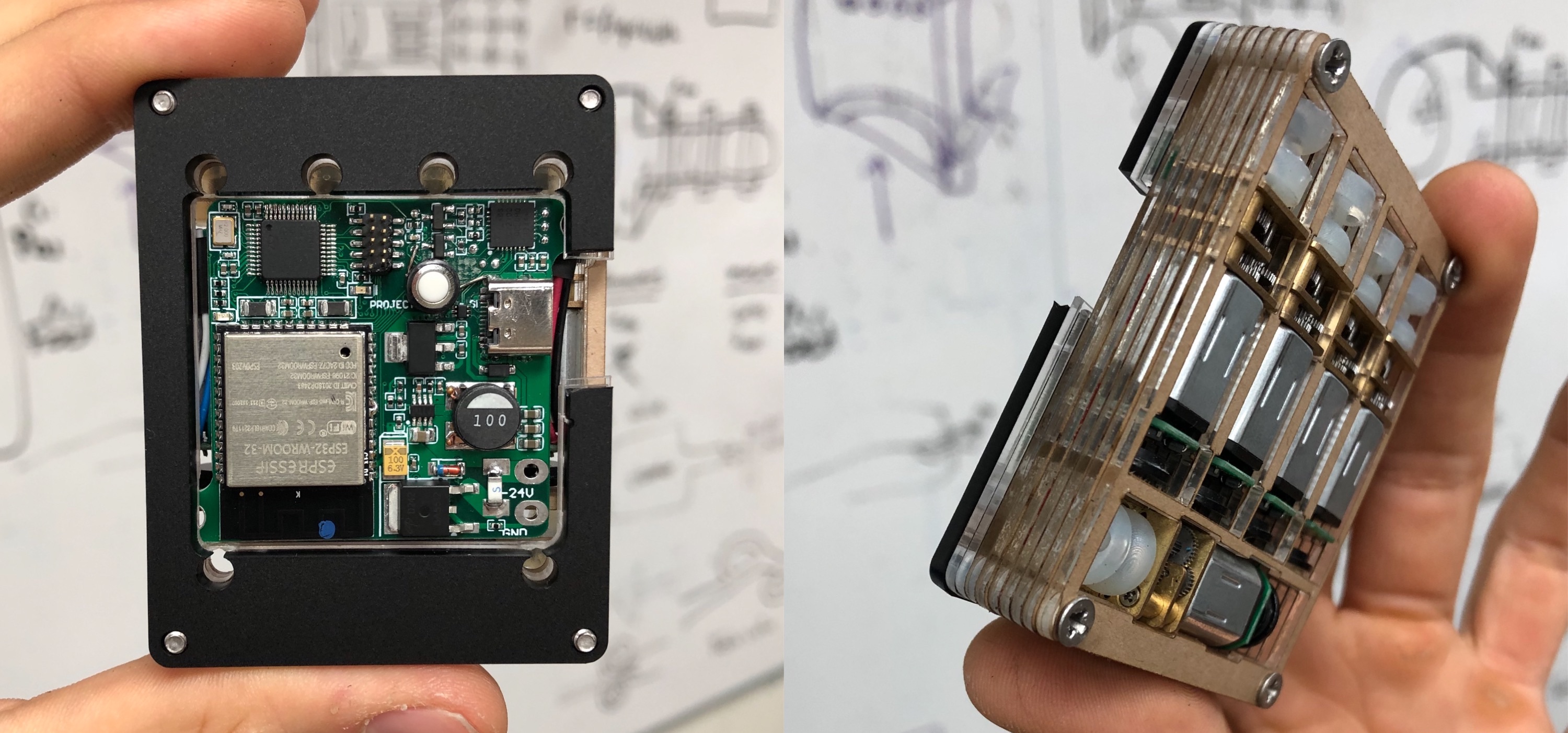

Our Team is committed to take the concept of modular prosthetics a step further, continuing to bridge the gap between expensive robotic arms and 3D printed prosthesis. We are designing and developing Sparthan, a modular electronics kit, compatible with existing prosthetic hand models, which will enable intuitive hand control and movements.

This is a developer preview of the Sparthan module. We designed it to be compact and powerful, easy to embed in existing 3D printable prosthetic hands.